Fully Automatic Powder Coating Line for Pallet Rack (Built in USA)

Email: services@colourspray.com

Whatsapp: 8618958052290

Pallet Rack Powder Coating Line, Fully Automatic Powder Coating Plant

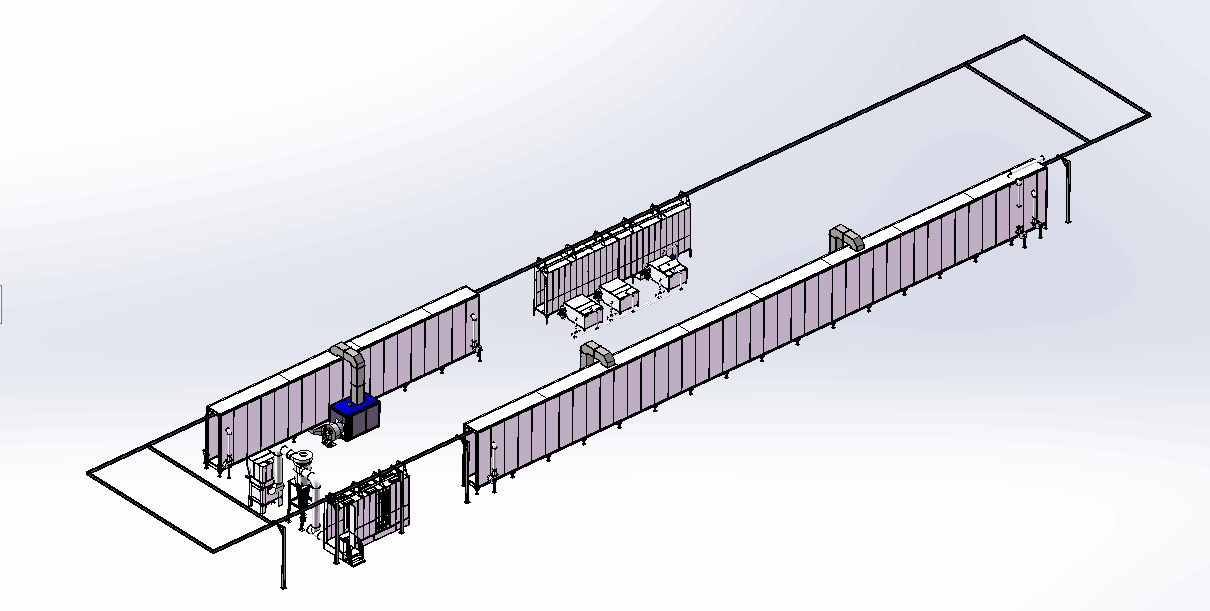

The fully automatic powder coating line is specially designed for USA customer to handle their warehouse pallet racks The plant includes pretreatment washer, automatic coating equipment, drying and curing tunnel oven cyclone recovery booth, automatic conveyor system suitable for high production rate and minimize labor cost.

Design Principle

Pallet Rack Item1: L408"*W5"*H60", Required Output: 35000pcs/year

Pallet Rack Item2: L288"*W8"*H12", Required Output: 3000pcs/year

Available Factory Area: 85000×36000×5400mm(L×W×H)

Full-automatic Powder Coating Line Configurations

1. Pretreatment - Spray Washing Tunnel

The washing tunnel type powder coating pretreament is by using many spraying nozzles and circulation pump to spray chemicals onto the processed objects. This process is suitable for big production capacity requirement. The spraying tunnel normally requires 316L Stainless Steel to be fabricated for the purpose of anti-rust and long service life.

2. Automatic Powder Coating Equipment

Automatic Spray Guns & Reciprocator: Driven by frequency motor, reciprocators carry spray guns (up to 24pcs) to move up and down in programmed stroke and speed.

Central Control Cabinet: A central cabinet combines all the gun controllers for integrated setting of parameters. Ensures reliability and controllability. Our intelligent powder coating gun is designed for perfectly coating different parts, whether flat panels or complex shapes.

Automatic Powder Feed Center: the system sieves and recycle large quantities of used powders without disturbing your online coating process, at the same time mixing with fresh powders for continuouse feeding, substantially eliminate wastage. The automatic cleaning function increase efficiency during color change.

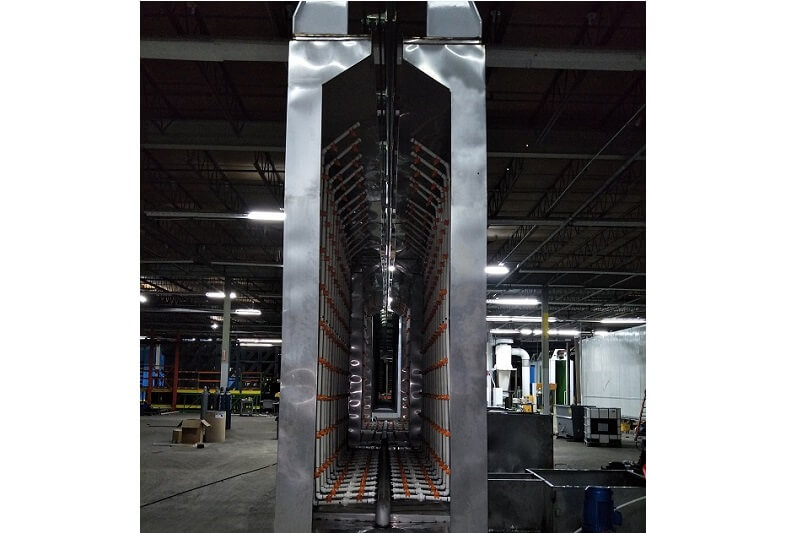

3. Automatic Powder Coating Cyclone Booth

Workparts automatically transported to the booth working station through conveyor, gets powder coating by automatic reciprocators. The booth flloor effectively transfer powder overspray for recycling. Usually made of PP or stainless steel material to improve recovery. Cyclone is necessary for fast color change demands. After filter unit is to capture superfine powder particles ensure the vented air is clean.

4. Drying and Curing Tunnel Oven

The tunnel oven is used after pretreatment washing for drying and as a Curing Oven for powder coating heating, it is designed for continuous operations. The product painted in these furnaces which are used in conveyor automatic facilities is constantly processed under desired temperature and time. Maximum painting efficiency is obtained with high capacities by means of those systems.

5. Overhead Conveyor System for Powder Coating Line

Overhead conveyors are the most commonly used type for surface finishing. The type of conveyor selected for your operation will depend on the weight, size and even the shape of the items being transported as well as the type of finishing process being applied. We design and supply full overhead conveyor system based on customers' requets, applied to manual or automatic lines,

![loading... [150x44]](https://shopsource.singoo.cc/1482/general/KmeFMJ8DaBPZ5AK6/5ad86023847be.png?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)